LATEST NEWS

最新消息

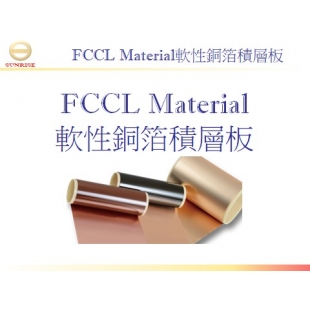

FCCL Material軟性銅箔積層板

無膠型軟性銅箔積層板(2-Layer FCCL):

高品質高性能 FCCL

電子產品應用領域朝輕量與微型化、高性能化的需求不斷演進,帶動FPCB軟性電路板產業的高速發展。

新一代高品質、高性能的2Layer無膠型軟性銅箔積層板(FCCL) 具有:

*極佳的機械強度與柔軟度

*高耐熱衝擊性與熱穩定性

*優良的尺寸安定性

*優異的物理及電氣性質

*卓越的光學特性

不但應用於嚴苛的靜態及動態撓折電路,亦廣泛應用於高密度軟板(HDI)、多層板、軟硬複合板,以及COF、CSP等IC驅動構裝,並能因應高頻高速傳輸的新世代需求。

優異的加工特性,在各項FPCB製程中無論是自動與半自動FPC生產設備皆能維持穩定品質。

高品質高性能 FCCL

電子產品應用領域朝輕量與微型化、高性能化的需求不斷演進,帶動FPCB軟性電路板產業的高速發展。

新一代高品質、高性能的2Layer無膠型軟性銅箔積層板(FCCL) 具有:

*極佳的機械強度與柔軟度

*高耐熱衝擊性與熱穩定性

*優良的尺寸安定性

*優異的物理及電氣性質

*卓越的光學特性

不但應用於嚴苛的靜態及動態撓折電路,亦廣泛應用於高密度軟板(HDI)、多層板、軟硬複合板,以及COF、CSP等IC驅動構裝,並能因應高頻高速傳輸的新世代需求。

優異的加工特性,在各項FPCB製程中無論是自動與半自動FPC生產設備皆能維持穩定品質。

MORE

DBP鋼帶壓合機(Double Belt Press)

IPCO 鋼帶 & DBP鋼帶壓合機:

(A)鋼帶:

適用於FCCL 2-Layer生產,具有絕佳的鋼帶品質與工藝,確保長期FCCL產品生產質量。

(B)DBP鋼帶壓合機:

Isochoric = Gap controlled 等容壓合

(A)鋼帶:

適用於FCCL 2-Layer生產,具有絕佳的鋼帶品質與工藝,確保長期FCCL產品生產質量。

(B)DBP鋼帶壓合機:

Isochoric = Gap controlled 等容壓合

MORE

新家裝潢,從這裡開始

ABOUT

US

US

關於我們

旭東昇公司成立於2004年,隨著科技發展與相關產業的需求,引進代理許多前瞻材料、設備與技術,提供創新高科技加值服務,多年餘來,我們已先後引進軟性印刷電路板、半導體、平面顯示器、與電動車電池產業的材料與設備。

現階段,我們更積極致力於節能產業、5G高頻行動穿戴及裝置、互聯與物聯網路解決方案的材料推廣,期待能陸續創造出高科技創新的價值。

今後,我們仍將本著誠信、創新、品質、服務的價值理念來服務大眾,以實現我們一貫的主張:創新的產品,優良的品質,感動的服務。希望我們的客戶與供應商多給予我們鞭策與支持,也期許我們大家一起共同努力,讓我們大家都成為全球性的企業,對世界社會有更多的貢獻。

PROJECT

產品介紹

MORE

TPX壓合離型膜(TPX Lamination Release Film)

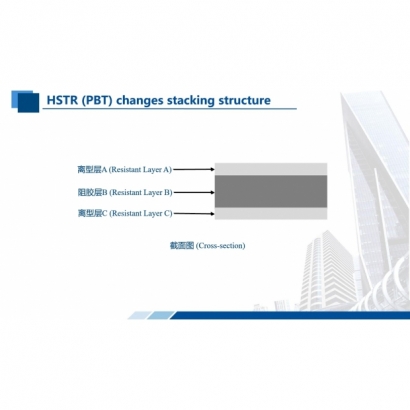

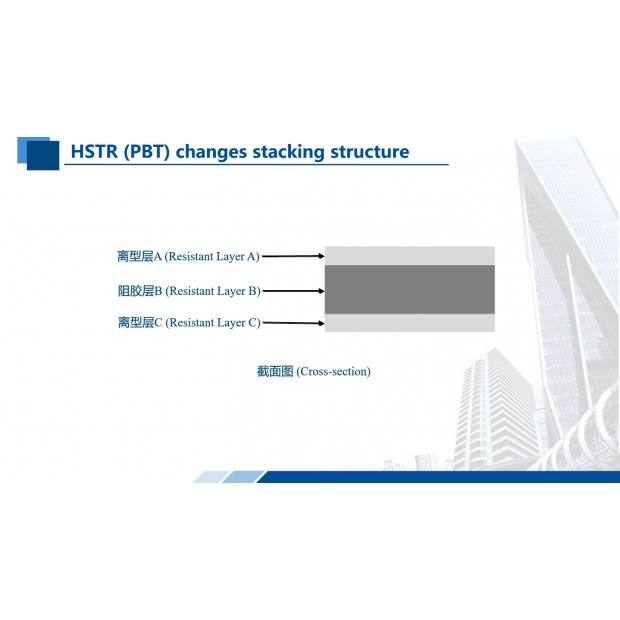

HSTR (PBT) :

叠板时将TPX及离型膜三合一优化成HSTR膜进行叠合,达到降低成本,提高叠合效率的目的。

产品介绍:

HSTR系列新型材料耐高温膜为采用耐高温稳定性之PBT为基材,上下层高性能离型性PBT进行高温离型以及阻胶,具有良好的高温耐热稳定性,离型性,以及突出的阻胶效果,具有良好的作业性,其高温下产生良好的塑性,且撕离无残留。

叠板时将TPX及离型膜三合一优化成HSTR膜进行叠合,达到降低成本,提高叠合效率的目的。

产品介绍:

HSTR系列新型材料耐高温膜为采用耐高温稳定性之PBT为基材,上下层高性能离型性PBT进行高温离型以及阻胶,具有良好的高温耐热稳定性,离型性,以及突出的阻胶效果,具有良好的作业性,其高温下产生良好的塑性,且撕离无残留。

MORE

FCCL Material軟性銅箔積層板

無膠型軟性銅箔積層板(2-Layer FCCL):

高品質高性能 FCCL

電子產品應用領域朝輕量與微型化、高性能化的需求不斷演進,帶動FPCB軟性電路板產業的高速發展。

新一代高品質、高性能的2Layer無膠型軟性銅箔積層板(FCCL) 具有:

*極佳的機械強度與柔軟度

*高耐熱衝擊性與熱穩定性

*優良的尺寸安定性

*優異的物理及電氣性質

*卓越的光學特性

不但應用於嚴苛的靜態及動態撓折電路,亦廣泛應用於高密度軟板(HDI)、多層板、軟硬複合板,以及COF、CSP等IC驅動構裝,並能因應高頻高速傳輸的新世代需求。

優異的加工特性,在各項FPCB製程中無論是自動與半自動FPC生產設備皆能維持穩定品質。

高品質高性能 FCCL

電子產品應用領域朝輕量與微型化、高性能化的需求不斷演進,帶動FPCB軟性電路板產業的高速發展。

新一代高品質、高性能的2Layer無膠型軟性銅箔積層板(FCCL) 具有:

*極佳的機械強度與柔軟度

*高耐熱衝擊性與熱穩定性

*優良的尺寸安定性

*優異的物理及電氣性質

*卓越的光學特性

不但應用於嚴苛的靜態及動態撓折電路,亦廣泛應用於高密度軟板(HDI)、多層板、軟硬複合板,以及COF、CSP等IC驅動構裝,並能因應高頻高速傳輸的新世代需求。

優異的加工特性,在各項FPCB製程中無論是自動與半自動FPC生產設備皆能維持穩定品質。

MORE

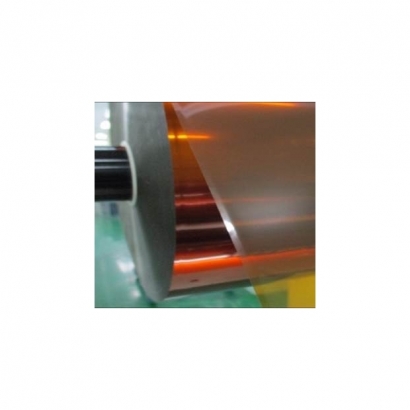

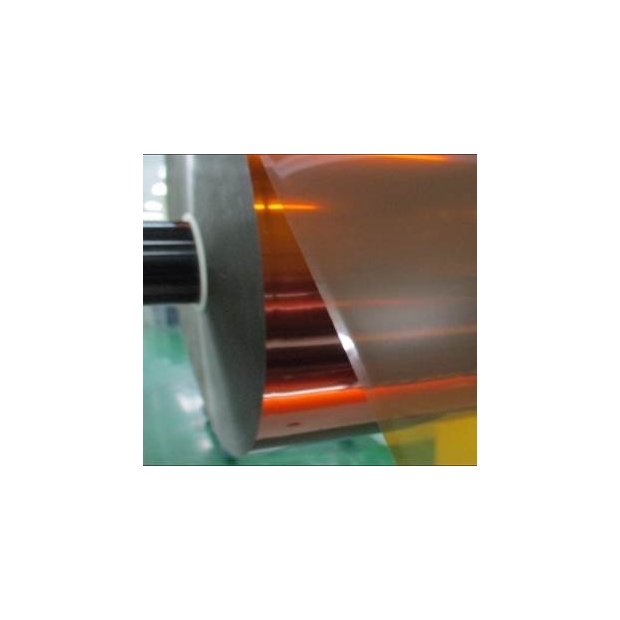

軟性銅箔積層板(FCCL)

無膠型軟性銅箔積層板(2-Layer FCCL):

AZOTEX®:高品質高性能 FCCL

由於電子產品的輕量微型化、高性能化的需求趨勢,帶動軟性電路產業的高速發展。佳勝科技以自有技術,推出新一代高品質高性能的無膠型軟性銅箔積層板(FCCL) AZOTEX®,擁有:

極佳的機械強度與柔軟度

高耐熱衝擊性與熱穩定性

優良的尺寸安定性

優異的物理及電氣性質

卓越的光學特性

不但應用於嚴苛的靜態及動態撓折電路,亦廣泛應用於高密度軟板(HDI)、多層板、軟硬複合板,以及COF、CSP等IC驅動構裝,並能因應高頻高速傳輸的新世代需求。

AZOTEX®具備極佳的加工特性,能適應不同的自動或半自動FPC設備,並能在複雜嚴苛的FPC製程中,維持耐久穩定的卓越性能。AZOTEX®亦具備長久的加工等待期,提供客戶寬裕的緩衝時間,使生產線規劃更具彈性。

AZOTEX®:高品質高性能 FCCL

由於電子產品的輕量微型化、高性能化的需求趨勢,帶動軟性電路產業的高速發展。佳勝科技以自有技術,推出新一代高品質高性能的無膠型軟性銅箔積層板(FCCL) AZOTEX®,擁有:

極佳的機械強度與柔軟度

高耐熱衝擊性與熱穩定性

優良的尺寸安定性

優異的物理及電氣性質

卓越的光學特性

不但應用於嚴苛的靜態及動態撓折電路,亦廣泛應用於高密度軟板(HDI)、多層板、軟硬複合板,以及COF、CSP等IC驅動構裝,並能因應高頻高速傳輸的新世代需求。

AZOTEX®具備極佳的加工特性,能適應不同的自動或半自動FPC設備,並能在複雜嚴苛的FPC製程中,維持耐久穩定的卓越性能。AZOTEX®亦具備長久的加工等待期,提供客戶寬裕的緩衝時間,使生產線規劃更具彈性。

MORE

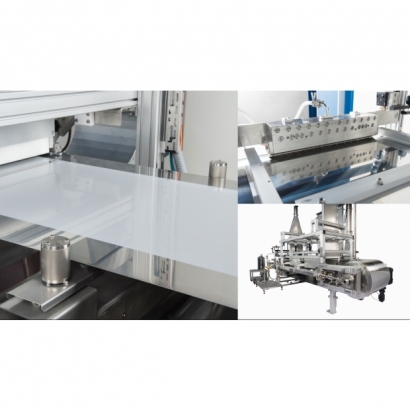

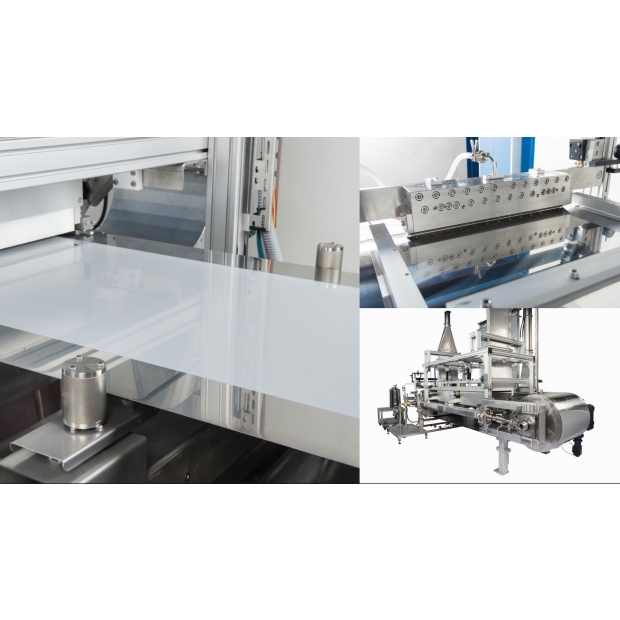

連續式塗布機台和文丘里乾燥系統(Continuous Film Casting Machine and Venturi Drying System)

持續的研發投資,加上我們在薄膜材料生產工藝技術方面的成熟經驗和專業知識,成功開發了用於薄膜流延應用的創新文丘里乾燥系統。

生產線從槽模開始,將精確控制的液體產品層施加到拋光鋼帶上。

它從這里通過文丘里乾燥器,在那裡溶劑(水性或有機物)被快速、高效地蒸發,並且使最終產品在橫向和縱向上幾乎完全沒有張力。

這種高精度系統顯著改進了鑄造工藝,使薄膜產品的生產公差極小,沒有任何結皮風險,並消除了最終材料中代價高昂的缺陷和缺陷。

這種間接乾燥解決方案的固有優勢還帶來了高度的能源效率。

雖然 IPCO 薄膜流延系統提供了許多獨特的市場優勢,但緊湊型文丘里乾燥器也可以與其他乾燥技術結合使用,包括傳統的衝擊式乾燥器。

出色的熱和氣流效果。

IPCO 文丘里乾燥器的主要優點是通過在乾燥膜上方使用可滲透的金屬泡沫來實現的。

調溫空氣流作用於這種泡沫狀金屬材料的上側,根據標準氣動定律在下側產生低負壓效果。

因此,形成恆定且均勻的吸入流,提供均勻的干燥效果。

這最大限度地減少了熱收縮,並消除了薄膜表面和層結構中結構缺陷的風險。

Ongoing investment in R&D, coupled with our proven experience and expertise in process technologies for the production of film materials, has resulted in the successful development of an innovative Venturi drying system for film casting applications.

The production line begins with a slot die that applies an accurately controlled layer of liquid product onto a polished steel belt.

From here it passes through the Venturi dryer where the solvent – aqueous or organic – is evaporated quickly, efficiently and in a manner that leaves the end product almost completely free of tension both laterally and longitudinally.

This high precision system dramatically improves the casting process, enabling the production of film products to exceptionally narrow tolerances without any risk of skin formation, and eliminating costly faults and imperfections in the final material.

The inherent benefits of this indirect drying solution also result in a high degree of energy efficiency.

While the IPCO film casting system offers a number of unique market benefits, the compact Venturi dryer can also be used in conjunction with other drying technologies including traditional impingement dryers.

Excellent thermal and air flow effects.

The key benefits of the IPCO Venturi dryer are achieved through the use of a permeable metal foam above the drying film.

A flow of tempered air is applied to the upper side of this foamlike metallic material, creating a low negative pressure effect on the lower side in accordance with the standard laws of pneumatics.

As a result, a constant and even suction flow is formed, delivering a homogeneous drying effect.

This minimizes thermally-induced shrinkage and eliminates the risk of structural defects in the surface and layer structure of the film.

生產線從槽模開始,將精確控制的液體產品層施加到拋光鋼帶上。

它從這里通過文丘里乾燥器,在那裡溶劑(水性或有機物)被快速、高效地蒸發,並且使最終產品在橫向和縱向上幾乎完全沒有張力。

這種高精度系統顯著改進了鑄造工藝,使薄膜產品的生產公差極小,沒有任何結皮風險,並消除了最終材料中代價高昂的缺陷和缺陷。

這種間接乾燥解決方案的固有優勢還帶來了高度的能源效率。

雖然 IPCO 薄膜流延系統提供了許多獨特的市場優勢,但緊湊型文丘里乾燥器也可以與其他乾燥技術結合使用,包括傳統的衝擊式乾燥器。

出色的熱和氣流效果。

IPCO 文丘里乾燥器的主要優點是通過在乾燥膜上方使用可滲透的金屬泡沫來實現的。

調溫空氣流作用於這種泡沫狀金屬材料的上側,根據標準氣動定律在下側產生低負壓效果。

因此,形成恆定且均勻的吸入流,提供均勻的干燥效果。

這最大限度地減少了熱收縮,並消除了薄膜表面和層結構中結構缺陷的風險。

Ongoing investment in R&D, coupled with our proven experience and expertise in process technologies for the production of film materials, has resulted in the successful development of an innovative Venturi drying system for film casting applications.

The production line begins with a slot die that applies an accurately controlled layer of liquid product onto a polished steel belt.

From here it passes through the Venturi dryer where the solvent – aqueous or organic – is evaporated quickly, efficiently and in a manner that leaves the end product almost completely free of tension both laterally and longitudinally.

This high precision system dramatically improves the casting process, enabling the production of film products to exceptionally narrow tolerances without any risk of skin formation, and eliminating costly faults and imperfections in the final material.

The inherent benefits of this indirect drying solution also result in a high degree of energy efficiency.

While the IPCO film casting system offers a number of unique market benefits, the compact Venturi dryer can also be used in conjunction with other drying technologies including traditional impingement dryers.

Excellent thermal and air flow effects.

The key benefits of the IPCO Venturi dryer are achieved through the use of a permeable metal foam above the drying film.

A flow of tempered air is applied to the upper side of this foamlike metallic material, creating a low negative pressure effect on the lower side in accordance with the standard laws of pneumatics.

As a result, a constant and even suction flow is formed, delivering a homogeneous drying effect.

This minimizes thermally-induced shrinkage and eliminates the risk of structural defects in the surface and layer structure of the film.

MORE

PI抗靜電耐高溫低黏著材料(PI Antistatic high temperature resistant low adhesion material)

PI抗靜電耐高溫低黏著材料(PI Antistatic high temperature resistant low adhesion material)

特性:

1.低黏著力 (1~5 gf/in)

2.耐高溫(200℃)

特性:

1.低黏著力 (1~5 gf/in)

2.耐高溫(200℃)

MORE

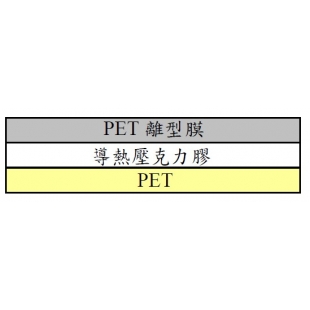

PET抗靜電耐高溫低黏著材料(PET Antistatic high temperature resistant low adhesion material)

PET抗靜電耐高溫低黏著材料(PET Antistatic high temperature resistant low adhesion material)

· 穩定的抗靜電性能

· 不殘膠

· 快速排氣效果

· 穩定的抗靜電性能

· 不殘膠

· 快速排氣效果